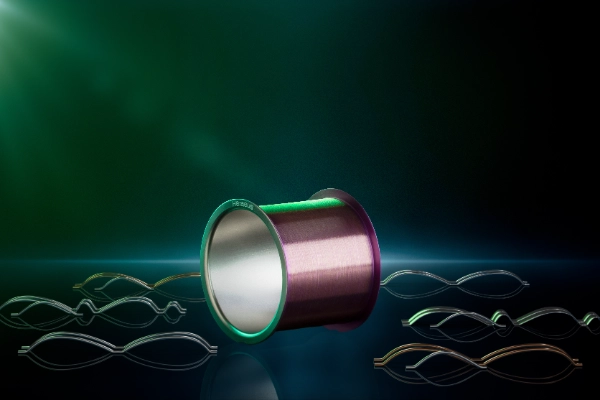

Copper and Coated Copper Bonding Wires

Copper wires offer significant cost savings compared to gold bonding materials

Excellent thermal and electrical properties

Diameters as thin as 0.6 mil, or in excess of 4.0 mils, for use in a wide range of applications

Copper bonding wires have grown in popularity as a means of making interconnects in an elecronics package, thanks to it's lower costs than materials such as gold, as well as high levels of electrical and thermal conductivity, and good reliability at high temperatures. In many applications, copper wire bonding can provide better performance and reliability than gold wire bonding.

Heraeus copper bonding wires are in many cases a good alternative to expensive gold-based solutions. With their fine diameters (0.6 mils or 15 µm) they are suitable for very small structures with ultra-fine pitch during wedge bonding and ball bonding processes. We also offer alloyed copper bonding wires in which alloy elements are added to the bare Cu wire such as in CuPd / AFPC core cu wire, and these copper bonding wires show advanced reliability and very good bondability.

Copper bonding wires are excellent for bonding in a ball / wedge process when using a reduced protective gas atmosphere. Cu wire bonding is also suitable for wedge / wedge bonding processes.

Applications include:

-

Computer:

- PC

- Tablets

- Servers & systems

- Consumer Electronics:

- Smartphones & phones

- TVs

- Imaging devices

- Wearable electronics

- Automotive:

- Body

- Safety

- Infotainment

- Chassis

- Powertrain

- Security

- Communications:

- Wireless

- Wired

- Satellite

- NFC

- Energy:

- Generation

- Transmission & distribution

- Storage

-aluminium.jpg)